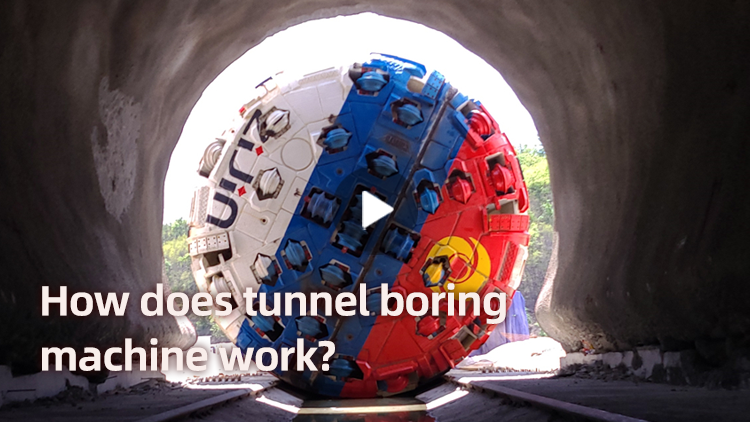

A tunnel boring machine (TBM), also referred to as full-section tunnel boring machine, is a machine used to excavate tunnels. It combines multiple technologies such as machinery, electronics, information technology, and artificial intelligence, being acclaimed as the "king of construction machinery." More than two decades ago, China did not have its own TBM. Today, Chinese-produced TBMs account for nearly 70 percent of the global market. China boasts the world's largest TBM fleet, with approximately 5,000 units.

In early 2000

the China Railway Group Limited decided to develop China's own TBM.

In 2008

China's first domestically developed earth pressure balance TBM with independent intellectual property rights made its debut, known as the "China Railway No. 1" TBM.

On February 6, 2009

the China Railway No. 1 TBM started working for a metro project in north China's Tianjin Municipality.

Since then, China's TBM industry has gained strong momentum, with a number of competitive manufacturers emerging and growing such as China Railway Engineering Equipment Group Co., Ltd. (CREG), China Railway Construction Heavy Industry Corporation Limited (CRCHI), and CCCC Tianhe Mechanical Equipment Manufacturing Co., Ltd. affiliated with China Communications Construction Company Limited (CCCC).

In 2012

China exported its first domestically produced TBM after China Railway won the bid for a metro construction project in Kuala Lumpur, Malaysia.

In 2015

China's "Zhang Heng" and "Zhan Tianyou" TBMs won contracts for metro projects in Singapore.

In 2016, a rectangular pipe jack TBM was awarded another contract, pioneering the entry of China's specialized TBMs into overseas markets.

On November 15, 2015

the first China-made railway TBM rolled off production line in Changsha. It reflects the country's pioneering breakthrough in key technical research and application of large-diameter TBM.

On July 3, 2017

CHCRI delivered its DZ397 TBM to Moscow for subway tunnel construction. This is CHCRI's first self-developed TBM tailored for the Russian market, marking the first time China's domestically-built shield machine enters the European market.

In 2019

the "China Railway No. 699" TBM won a bid for a railway project in northern Italy, marking the first application of China's advanced tunneling equipment in a country of European Union. In the same year, two domestically produced TBMs were contracted for a Paris metro construction project in France.

On September 15, 2023

a CRCHI TBM rolled off the production line in Changsha. It is Hunan's first independently developed high-end underground engineering equipment to be exported to Italy and even the EU market.

On October 12, 2023

a TBM main bearing with a diameter of 8.61 meters rolled off the production line at a CRCHI facility in Changsha. It was the world's largest-diameter main bearing for TBM, boasting the heaviest weight and highest bearing capacity.

On September 12, 2024

a CRCHI TBM rolled off the production line in Changsha. This machine is scheduled to be delivered to Cluj-Napoca, Romania's second-largest city, for the construction of a local subway project. It marks the first Chinese TBM exported to Romania.

On October 31, 2024

China's self-developed TBM with the biggest diameter rolled off the production line. The machine, with a maximum excavation diameter of 16.64 meters, was produced in Changsha, marking a breakthrough in the development and industrialization of the 16-meter-class domestic super-large diameter tunnel boring machines.

On December 18, 2024

a CRCHI TBM rolled off the production line in Changsha, which is scheduled to be exported to Zambia for mining tunnel construction.

On February 17, 2025

the CRCHI TBM "No.1 Shuangjing" rolled off the production line in Changsha. It will be used for the construction of the Tina River Hydropower Development Project of Solomon Islands. This marks the first time a China-made TBM being exported to the Solomon Islands.

UPDATES

UPDATES